Our Process

At INEX, we believe that delivering excellence starts with a clear, customer-focused process. Every project is handled with care, precision, and a deep commitment to quality at every stage.

Collaborating with you to turn ideas into precise engineering designs.

Using PLC-controlled Aluminium extrusion presses to ensure high strength and low waste.

Precision sawing, drilling, punching and tapping machining activities for complex, custom Aluminium parts with unmatched precision.

We offer the following array of surface treatment finishes in addition to the mill finish of extruded products:

- Brushing/Satin Finish: Achieved by applying a brushed abrasive to the surface, creating a uniform, directional texture. This provides a refined, matte appearance.

- Polishing/Buffing: Involves abrasive compounds and buffing wheels to create a smooth, highly reflective, mirror-like surface.

- Abrasive Blasting (Shot Blasting): Propels abrasive media (steel grit) at high velocity onto the surface, creating a uniform matte, textured, or etched finish depending on the media and pressure.

- Grinding/Sanding: Used to flatten surfaces, remove significant imperfections, or prepare for subsequent finishing. Leaves fine striations.

-

Anodizing (Electrochemical): An electrochemical process that thickens the naturally occurring oxide layer on the Aluminium surface.

- Clear/Standard Anodizing: Produces a translucent oxide layer, showcasing the metallic lustre underneath.

- Colour Anodizing: Dyes are absorbed into the porous oxide layer before sealing (e.g., black, bronze, champagne, blue, red).

- Chromate Conversion Coatings (Chemical): Forms a thin, protective iridescent yellow to clear film often used as a primer or corrosion inhibitor.

-

Applied Coatings: Involves applying a distinct layer onto the Aluminium surface.

-

Powder Coating: Electrostatic dry powder cured in an oven. INEX is an approved applicator of:

- Akzo Nobel (Interpon Powder Coatings)

- Berger

- Asian Paints

- Liquid Painting (Wet Paint): Used for architectural panels and industrial components.

- Sublimation (Wood Grain/Custom Patterns): Transfers custom patterns onto powder coat using heat and vacuum.

-

Powder Coating: Electrostatic dry powder cured in an oven. INEX is an approved applicator of:

Design & Consultation

Collaborating with you to turn ideas into precise engineering designs.

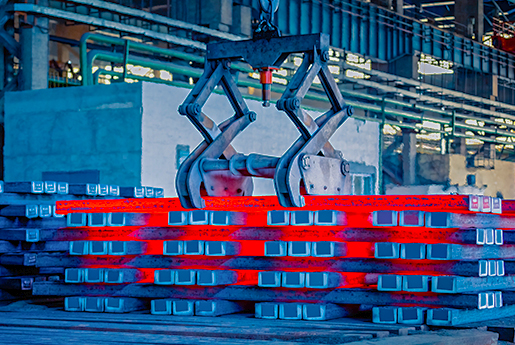

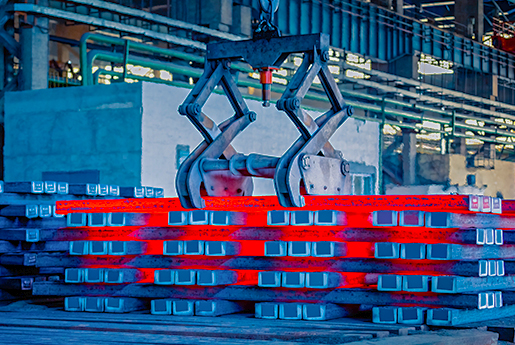

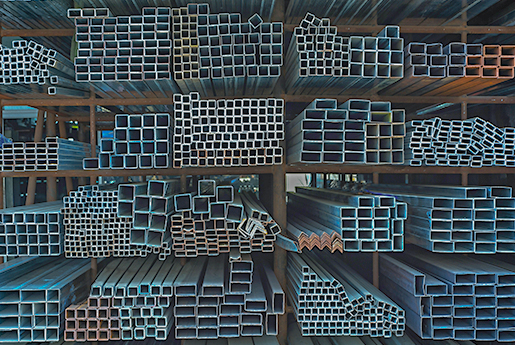

Extrusion

Using PLC-controlled Aluminium extrusion presses to ensure high strength and low waste.

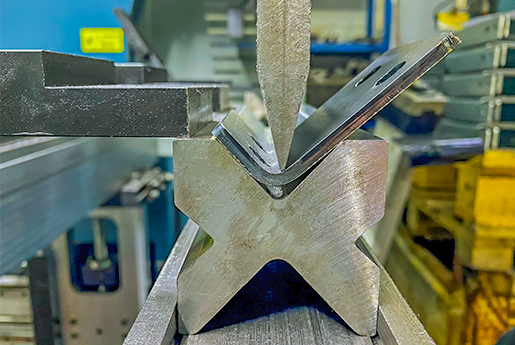

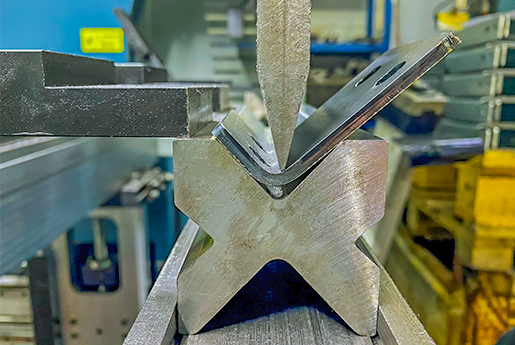

Fabrication

Precision sawing, drilling, punching and tapping machining activities for complex, custom Aluminium parts with unmatched precision.

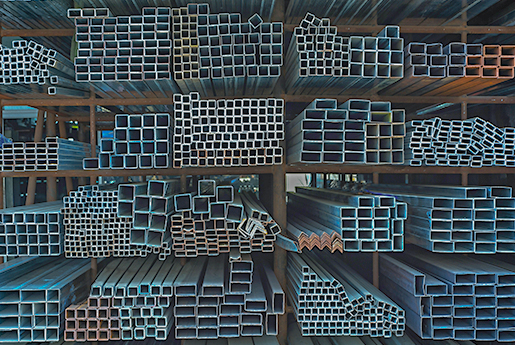

Finishing

We offer the following array of surface treatment finishes in addition to the mill finish of extruded products:

- Brushing/Satin Finish: Creates a uniform, matte texture with a directional grain.

- Polishing/Buffing: Produces a reflective, mirror-like surface using abrasive compounds.

- Abrasive Blasting: Applies steel grit at high velocity to create uniform matte or etched finishes.

- Grinding/Sanding: Smooths surfaces or removes imperfections with fine striations.

-

Anodizing (Electrochemical): Thickens the oxide layer on Aluminium for protection.

- Clear/Standard: Translucent layer revealing metallic shine.

- Colour: Dye-infused oxide layer (e.g., black, bronze, red).

- Chromate Conversion Coatings: Thin, iridescent protective film used for corrosion resistance.

-

Applied Coatings: Distinct finish layers for aesthetics and performance.

-

Powder Coating: Electrostatic dry powder cured in oven. INEX is an approved applicator of:

- Akzo Nobel (Interpon)

- Berger

- Asian Paints

- Liquid Painting: Wet paint for panels and components.

- Sublimation: Transfers wood grain/custom patterns using heat & vacuum.

-

Powder Coating: Electrostatic dry powder cured in oven. INEX is an approved applicator of: